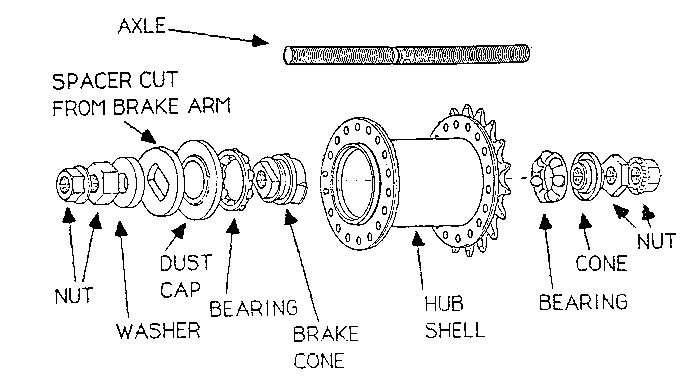

The hub is the middle part of the wheel, to which the inside ends of the spokes attach. It consists of an axle which attaches to the fork ends; a shell, to which the spokes attach; and bearings to connect the axle to the shell, permitting the shell to revolve around the axle. In the case of the rear hub, the shell would also have a provision for attaching the rear sprockets.

The hub is the middle part of the wheel, to which the inside ends of the spokes attach. It consists of an axle which attaches to the fork ends; a shell, to which the spokes attach; and bearings to connect the axle to the shell, permitting the shell to revolve around the axle. In the case of the rear hub, the shell would also have a provision for attaching the rear sprockets.

The clincher tire is used on 99% of all bikes and consists of an outer tire with a U-shaped cross section and a separate inner tube (basically a doughnut shaped rubber balloon) with air pressure keeping everything in place. The outer tire is made up of 3 parts:

- The beads: two hoops of strong wire that make up the edge of the tire and holds the tire to the rim

- The fabric cords forming the body of the tire, woven between the two beads.

- The rubber that covers all the other parts is mainly there to protect the fabric and has no structural importance. The thicker rubber that contacts the road is called the tread.

Wheel truing is the process to make a wheel spin straight and round by evening out the tension in the spokes. The typical bike wheel is composed of a rim suspended with tensioned spokes around a center hub. Each spoke pulls on a section of rim. Spokes coming from the right side hub flange pulls the rim to the right and vice versa. Spoke attached at the rim are then offset in a left-right-left-right pattern to counter the pull of the other side.

How is spoke tension adjusted?

By tightening or loosening a threaded nut, called the nipple, at the end of the spoke. Spoke nipples come in different sizes so the correct wrench must be used. The correct wrench is the smallest size that can be used. Make sure that the wrench is fully engaged before turning.

Are you tightening the spoke or the nipple?

You are ALWAYS rotating the nipple. Therefore, when you true a wheel and you view the wrench and nipple upside down, you will tighten by turning the wrench left. Just imagine a screwdriver at the nipple end and turn clockwise/counter-clockwise as needed.

Steps for Lateral Truing

- Carefully inspect the wheel for broken/bent spokes

- Grab the rim and flex it side to side to check for play in the hub bearings. If the bearings are loose, the wheel will clunk side to side. The hub will need to be tightened before you true the wheel, or else the wheel will behave erratically

- Mount the wheel in the truing stand, with the right side of the wheel on the right side of the stand

- Where the rim scrapes, loosen the spoke(s) closest to it and tighten the spoke(s) on the opposing end. This approach will pull the rim away from the caliper. When correcting a wheel that is laterally out of true, always adjust spokes in pairs: one spoke coming from one side of the wheel, the other from the opposite side.

- Check the wobble first on one side of the wheel and then the other, adjusting spokes accordingly, so that you don't end up pulling the wheel off-center by chasing wobbles only on one side. As the wheel gets closer to true, you will need to decrease the amount you turn the spokes to avoid overcorrecting.

- You should always pre-stress the spokes and re-adjust before riding. Failure to do so can cause broken spokes later. There are two ways to do this:

- Squeeze together parallel spokes on both sides of the rim OR

- Rest the wheel sideways on the floor and gently push down on both sides of the rim, all the way around the wheel in 1/8 increments

- Squeeze together parallel spokes on both sides of the rim OR

- After pre-stressing the spokes you will have to re-check and make some minor adjustments. If the rim looks severely warped afterwards, it means your spoke tension was too high. Loosen all spokes 1/2 turn and re-true the wheel.

No comments:

Post a Comment